In the Meler bead applicators, you can choose between two pneumatic control versions, air opening-air closing AOAC or air opening-spring closing AOSC. Starting with a basic design, the application elements are configured with:

- Different numbers of modules.

- The individual activation of each module or a group of them by solenoid valves.

- Other features such as the type of temperature sensor and connector, side or rear entry of adhesive, different fittings and solenoid valves.

- Different types of nozzles with different diameters.

Meler bead applicators have the option of including a filter. This choice largely prevents nozzles from becoming blocked and subsequent production stoppages.

Manual Applicator for Bead Applications

High Precision and Uniformity

Easy to handle, it is activated by an ergonomic trigger. It is lightweight and ensures high precision and uniformity in adhesive application. Heat distribution is completely even.

Great Flexibility

Its complete rotation allows greater flexibility and a wide range of applications. It can also be adapted to any Meler melter using manual hoses, forming a compact unit.

NC Series Applicator

Compatibility

The applicators are compatible as regards to their dimensions and electrical and hydraulic connections. They can be configured to order to adapt to any application need, without any special designs.

Uniformity and Accessibility

Stable temperature to the output of the module, allowing a uniform flow rate over time. Easy access to the internal components by removing the side plates for their maintenance and repair.

HS Microprecision Series Applicators

For High Speed Machines

Applicator for high speed machines that combines the design of the module with the features of the solenoid valve, offering both a precise dot and bead application.

Highly Repeatable Response Time

It’s reduced activation response time, the high repeatability of the response time during its service life and its high cycle capacity make it ideal for demanding applications such as packaging or graphic arts. Built-in filter to prevent obstructions in the nozzle

Directable Microprecision Series Applicators

Applicator with two directable modules for gluing different box formats.

Features

• Precise bead application (dots or lines).

• Double action (AOAC) activator.

• Supports smaller distances than the minimum centre-to-centre distance of the modules.

Adjustable Bead Distance

A simple swivel of the modules allows various box formats using a single hose. Adjusting the two microprecision modules helps reduce downtime when changing the product.

MU Series Applicators

Wide Configurable Range

It is a fully adjustable range that can be adapted to any application need. This includes the entire range of MSU or MDU long-life modules.

Uniformity and Accessibility

Stable temperature maintained to the module’s output, allowing a uniform flow rate over time. Easy access to the internal components by removing the side plates to facilitate their maintenance and repair. In single action (AOSC) and double action (AOAC) versions.

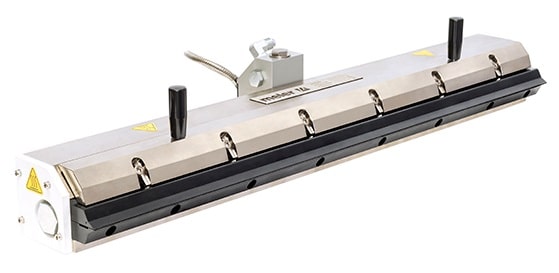

Multiline Series Applicators

For applications to hermetically seal the bottoms and tops of product cases.

Sturdy & Configurable Design

Based on the MSU or MDU applicator bodies, they include high durability MSU.MT or MDU.MT modules.

Hermetically Sealed Packaging

The minimum distance between the tips of each nozzle ensures a hermetic seal all around the box. The inviolability of the packaging is ensured, preventing product leaks and protecting its contents against any contamination from the outside.

Meler Swirl & Spray Adhesive Applicators

Meler’s swirl application elements range covers a broad spectrum of different application requirements, from the simplest, the E series, of reduced dimensions with direct entry of air, moving on to the ECA (control of opening and common air) and ECAI (control of opening and independent air) multimodule models with air heating block incorporated in the applicator itself, through to the ECA-CI and ECAI-CI series with independent heating block for more demanding applications.

The extensive range of nozzles with different diameters in the adhesive and air holes are added to the various configuration possibilities of these types of application elements to always achieve the best application results:

- Broad glued surface with perfect contour control.

- High cycle frequency for intermittent applications.

- Simple installation thanks to built-in air heater.

- Adhesive savings.

- Gluing strips on rough or irregular surfaces.

- Design of multiple injection applicators according to application needs.

Manual Applicator for Swirls & Spraying Applications

High Precision and Uniformity

Easy to handle, it is activated by an ergonomic trigger. It is lightweight and ensures high precision and uniformity in adhesive application. Heat distribution is completely even.

Great Flexibility

Its complete rotation allows greater flexibility and a wide range of applications. It can also be adapted to any Meler melter using manual hoses, forming a compact unit.

E-Series Applicators

Sturdy & Configurable Design

With direct air intake into the swirl module. Used with standard applicators of the MSU or MDU series. Includes the MSU.E or MDU.E modules. Swirler air adjustment using an external pressure regulator.

ECA/ECAI Series Applicators

Adhesive Savings in Broad Strip Applications

This applicator is used for swirl applications with integrated air heating. Adhesive savings. Larger gluing surface achieved while applying a smaller quantity of adhesive. Enables the gluing of strips to rough or irregular surfaces.

Quick and Versatile

High cycle frequency for intermittent applications. Very simple installation thanks to the built-in air heating. Possibility of configuring single action (AOSC) and double action (AOAC) multimodule versions, with shared or individual control over the length of the application and width of swirl of each module.

Spray Series Applicators

Adhesive Savings in Broad Strip Applications

This applicator is used for swirl applications with integrated air heating. Adhesive savings. Larger gluing surface achieved while applying a smaller quantity of adhesive. Enables the gluing of strips to rough or irregular surfaces. Adhesive application in a broad spiral shape with a width of up to 400 mm (depending on the adhesive and application conditions).

Incorporated Spray Air Heating and Regulation

Simple installation thanks to the built-in air heating. Spray air adjustment by means integrated flow regulators.

Meler Intermittent Applicators

The entire range adapts perfectly to different types of adhesives, processes and production speeds.

The coating heads range is modular and configurable with the following parameters:

- Intermittent or continuous application.

- With ball-closing modules for intermittences with a low-medium frequency.

- With negative closing modules for high or very high frequencies.

- With fixed or adjustable coating width from 10 to 2200 mm.

Advantages

Meler’s coating applicators are characterised by:

- Controlled thickness of adhesive coat.

- High resistance of materials used against wear and strain.

- Robust, accurate and durable closing devices (modules).

- In intermittent applications, very precise cutting of the adhesive is obtained even when the machine is at high cycle and speed frequencies.

CRCN Series Head

For Precise Application using Different Patterns

Perfect control of the application of the adhesive in a broad spectrum of applications. Suitable for paper and cardboard surfaces, film, labels, tapes, envelopes, forms, textiles, etc.

Quick, Clean Cut-off

High-speed closing system. Provides a perfectly clean cut-off at the end of application, by using injector modules with differential pneumatic control. High-capacity, easy to clean adhesive filtering system.

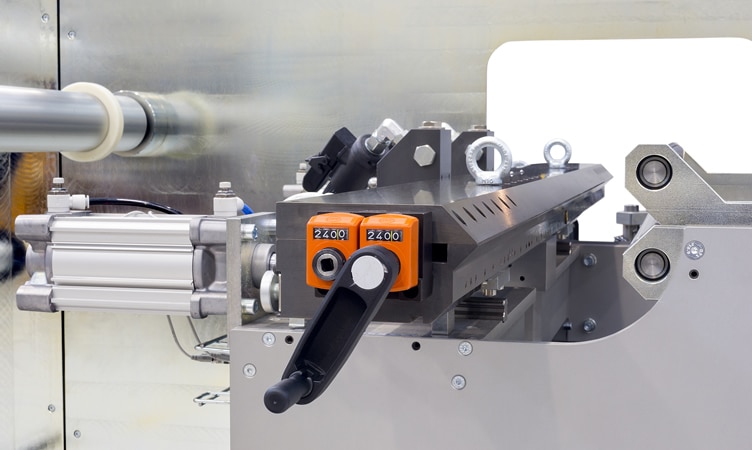

Adjustable Edge Banding Slot Gun

For Gluing and Sealing the Edges of Boards

The flexibility of the edgebandhead covers a broad range of applications, for EVA and PUR-based adhesives.

Easy to Use and Low Maintenance

The application strip is easily adjusted using a swivel control, showing the measurement on a graded rule. The swivel mount allows quick, easy installation and adjustment on the board.

Book Spine Gluing with PUR Adhesive Head

High Quality Finish

Automatic gluing of the cover to the book spine. Coating applicator with variable application width (0-60 mm or 0-100 mm) with fast cutting module. Provides books with a high-quality finish.

Clean and Precise

Precise adjustment of application width using a worm wheel and screw. Application thickness of 0.3 to 0.4 mm: half of that in conventional applications. Prevents overflow and thus soiling of the cutting blades

Meler Continuous Applicators

Manual Applicator for Coating Operations

High Precision and Uniformity

Easy to handle, it is activated by an ergonomic trigger. It is lightweight and ensures high precision and uniformity in adhesive application. Heat distribution is completely even.

Great Flexibility

Its complete rotation allows greater flexibility and a wide range of applications. It can also be adapted to any Meler melter using manual hoses, forming a compact unit.

For High-Flow Continuous Applications

For continuous coating where the final cut-off does not require precision or drip protection.

Features

- Coating widths from 300 mm to 2,000 mm.

- Versions with shim plate or machined nozzle cover to match the application pattern.

- Use in continuous operation winding-unwinding machines.

- Used for high-flow applications with a minimum grammage of 20 g/m2.

Coating Head for Gluing Labels to Jars, Cans & Bottles

Modular designs for one or more labels, with independent control of the application injector modules. Flow adjustment by means of small regulators inserted into the applicator.

Configurable Design

- Possibility of configuring single action (AOSC) and double action (AOAC) multimodule versions.

- Versions with shim plate or machined nozzle cover to match the application pattern.

- Coating widths of up to 375 mm.

Application Fields

Applications on paper and cardboard surfaces, film, labels, tapes, mail bags, etc. on machines for covering profiles with paper or PVC, plastic bag manufacturing, etc. Minimum grammage 20 g/m2.

Adjustable Coating Head

Continuous coating head with manual adjustment of strip width.

Features

- Independent sheets with adjustment from the centre towards the edges.

- Standard application width adjustable from 20 to 350 mm.

- Has a heated hydraulic valve fixed to the head, with independent control, keeping the adhesive at a uniform temperature.

- Adjustment activation via levers on the same side (operator’s side).

- Operating flexibility: centre of machine or edge of paper, coating on horizontal or vertical substrate.

Efficient Adhesive Use

- Heated hydraulic valve fixed to the head, with independent control, keeping the adhesive at a uniform temperature.

- Use with gear melters. They allow precise dispensing, with quality finishes and adequate adhesive consumption.

- Optional roller system to move the strip nearer/further away, allowing the substrate to be moved away from the coating lip when the machine stops.

Contact Form

If you think the Meler Hot Hot & Liquid Glue Adhesive Applicator might be perfect for your business, please fill out the form below. Our experts sales consultants will be able to accurately determine what model, glue and usage will be perfectly suited to your specific application.

Call Our Gluing Experts

If you’d like to speak to one of our Gluing Systems experts please call us on

+61 3 9330 2678

Genuine 24/7 Service & Support

Our experienced and highly trained service technicians are only a phone call away, day or night, should you require advice, essential spare parts or a technicians on-site assistance with your hot glue equipment.

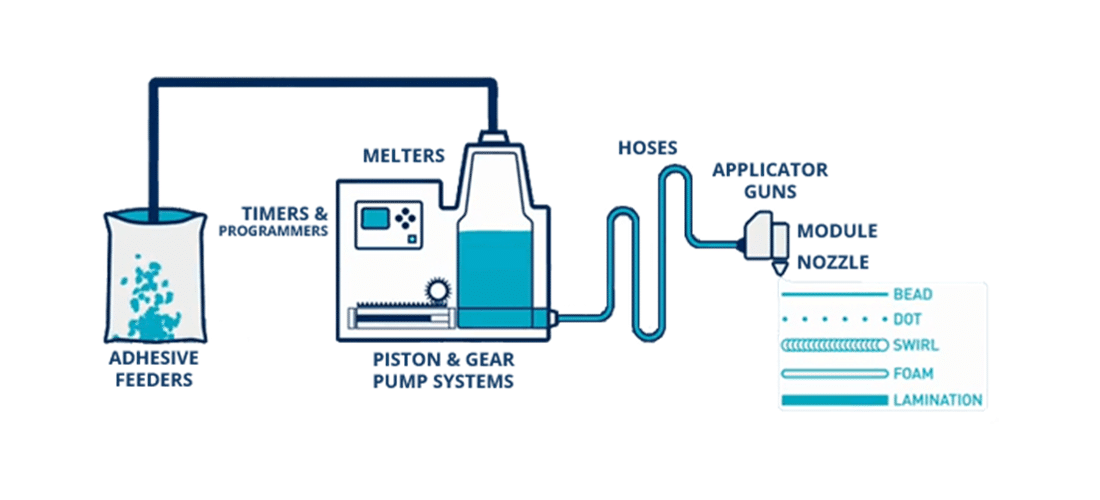

How Does A Meler

Gluing System Work?

This video provides an overview of the full system functionality of a Meler gluing system and highlights the parts of each Meler system, from the smallest to the largest, that make up a Meler Hot Melt system to deliver hot melt glues to various product.